CAD/CAM Software for CNC Machines

Simple, yet powerful integrated CAD/CAM software for CNC Machines

- FlashCut CAD’s intuitive user interface makes it simple to draw and edit any 2D and 2.5D shape

- Simple import of any 2D drawing

- Convert any bitmap image or photo into a toolpath (outline or centerline)

- Advanced Boolean operations like welding multiple shapes into one

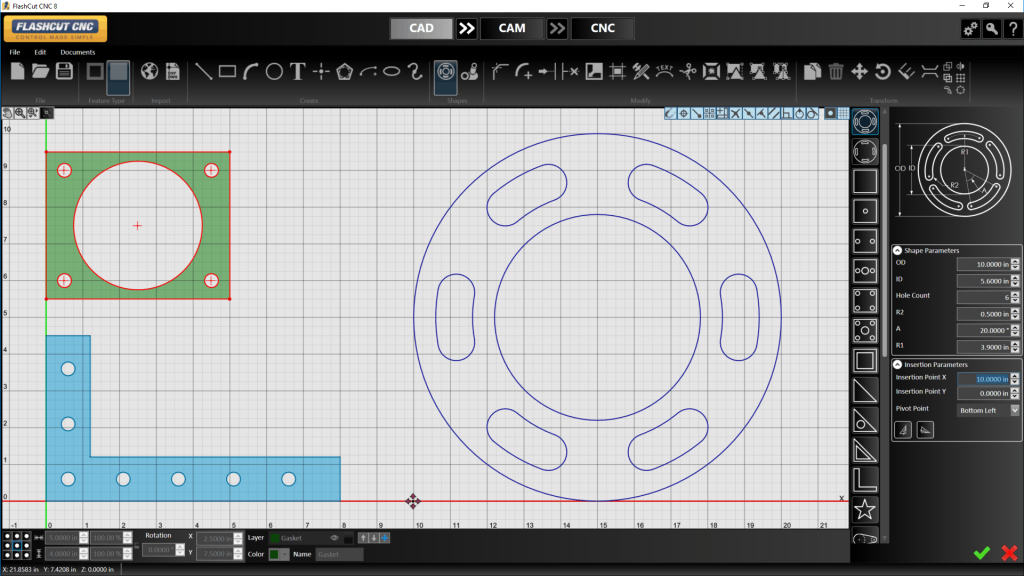

- Shape library allows you to instantly draw and customize common shapes

- DXF export for sharing drawings with other CAD programs

- Fix tool finds and corrects CAD mistakes instantly

- Easily bridge internal cut outs such as the center of an “O”

Our intuitive CAM Software creates accurate toolpaths instantly

- FlashCut 2D and 3D CAM generates perfect toolpaths for plasma, oxyfuel waterjet, laser, or marking

- Automatic generation and simple manipulation of lead-ins and lead-outs

- Automatic generation of fixture tabs

- Automatic kerf compensation

- Simple import of DXF or DWG files

- Sheet management for multiple sheets per job

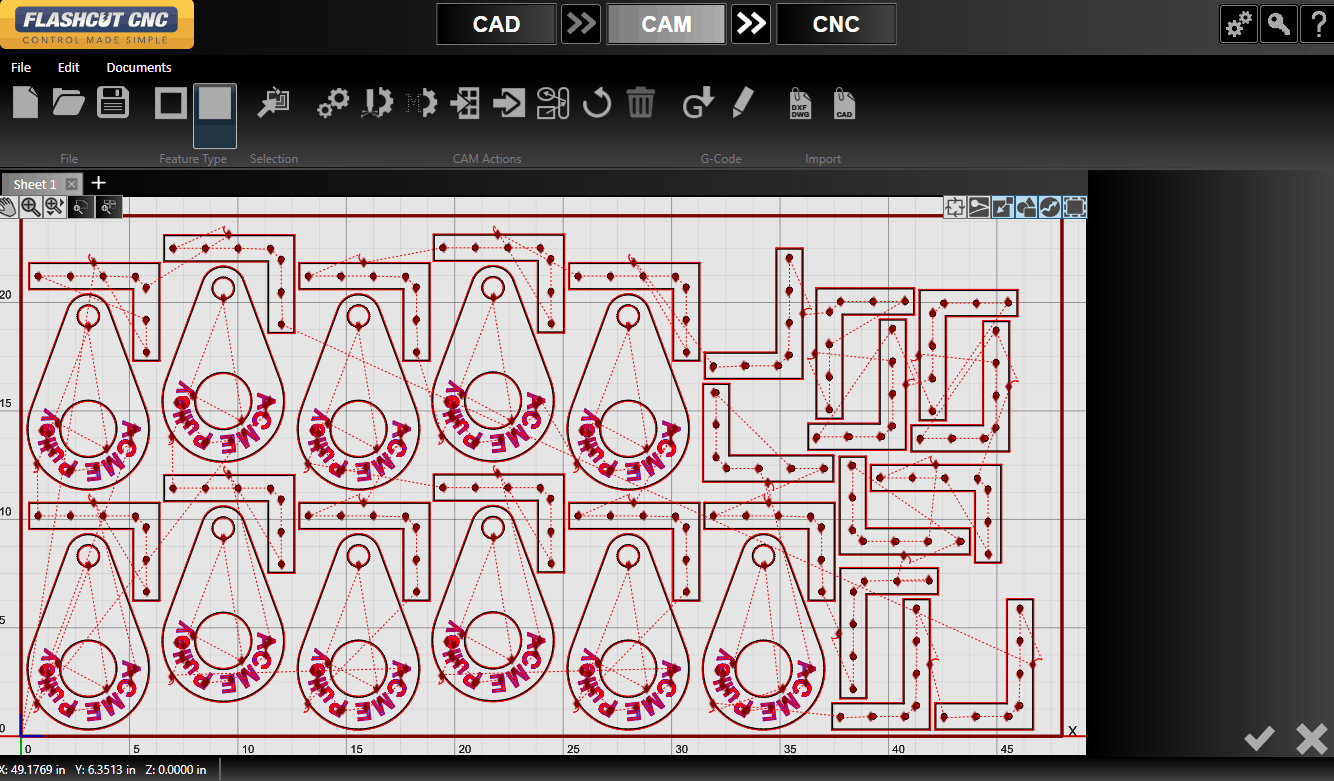

- Advanced true shape nesting includes nesting of multiple CAD or DXF files and multi-sheet nesting

- Corner looping strategies for reducing dross in corners

- Editable plasma and oxyfuel charts for many models from Hypertherm® and Thermal Dynamics® and other popular models takes the guesswork out of important cutting parameters like feedrate, kerf, cut height and voltage

There are many varieties of FlashCut CAD/CAM to suit your unique needs, budget or application. The chart below outlines the differences between our Standard and Pro versions of the software. It also includes a-la-carte features that can be added to either the Standard or Pro editions for an additional fee.

Software Features

Standard FeaturesAdditional Pro FeaturesAdditional Premium FeaturesPREM + REMA-La-Carte Add-On Features

| Part # | Description | V5 | V6 | V7 | V8 | V9 | V10 | ||

|---|---|---|---|---|---|---|---|---|---|

Standard Features | FCS-10-CCC-STD

+Quote

Loading…

| Standard 2D CAD/CAM/CNC Software | |||||||

| Basic Oxyfuel Supportcamcnc | × | × | × | × | × | × | |||

| Basic Plasma Supportcamcnc | × | × | × | × | × | × | |||

| Customizable Cut Charts for Differing Materials and Thicknessescamcnc | × | × | × | × | |||||

| Improved M-Code and Fab-Head Configurationcamcnc | × | × | × | × | |||||

| Centerline Image Importcad | × | × | × | × | |||||

| Chamfer & Cornering Toolcad | × | × | × | × | × | ||||

| DXF/DWG Importcad | × | × | × | × | × | × | |||

| Free Form Stretching and Manipulationcad | × | × | × | × | |||||

| Layer Supportcad | × | × | × | × | |||||

| Measuring Toolcad | × | × | × | × | × | ||||

| Silhouette Image Importcad | × | × | × | × | × | × | |||

| Assign Different Operations to Each Partcam | × | × | × | × | |||||

| Automatic Kerf Compensationcam | × | × | × | × | × | × | |||

| Customizable Post Processorcam | × | × | × | × | × | × | |||

| Cut Sequencingcam | × | × | × | × | |||||

| Custom views of Kerf Width, Cut Direction , Toolpath, Rapids and Part Geometrycam | × | × | × | × | |||||

| Cutout or Part Modecam | × | × | × | × | × | × | |||

| Drag, Delete, Rotate, Copy parts on the nestcam | × | × | × | × | |||||

| Graphical editing of Lead-in Lead-out locationcam | × | × | × | × | |||||

| Grid Nestingcam | × | × | × | × | × | × | |||

| Operation Sequencingcam | × | × | × | × | |||||

| Overburn Supportcam | × | × | × | × | |||||

| Tabbingcam | × | × | × | ||||||

| Commonly Used Plate Listcam | × | × | × | × | |||||

| Customizable Lead-in, Lead-out Strategiescam | × | × | |||||||

| Dry Runcnc | × | × | × | × | × | × | |||

| Jump to Linecnc | × | × | × | × | × | × | |||

| Kerf Crossing Detectioncnc | × | × | × | × | × | × | |||

| Momentary Runcnc | × | × | × | × | |||||

| Run File Forward and Backwardscnc | × | × | × | × | |||||

| THC Performance History Chartcnc | × | × | × | × | |||||

Additional Pro Features | FCS-10-CCC-PRO

+Quote

Loading…

| Pro 2D CAD/CAM/CNC Software | |||||||

| Advanced Oxyfuel Supportcamcnc | × | × | |||||||

| Advanced Piercing (Included with Advanced Plasma)camcnc | × | × | |||||||

| Advanced Plasma Supportcamcnc | × | × | × | × | × | × | |||

| Printing Support for Part Number Labels, Nest Report and Nest (when licensed for the feature)camcnc | × | × | × | ||||||

| Animated Cutting Simulationcamcnc | × | × | × | × | |||||

| Feature-Based Processescamcnc | × | ||||||||

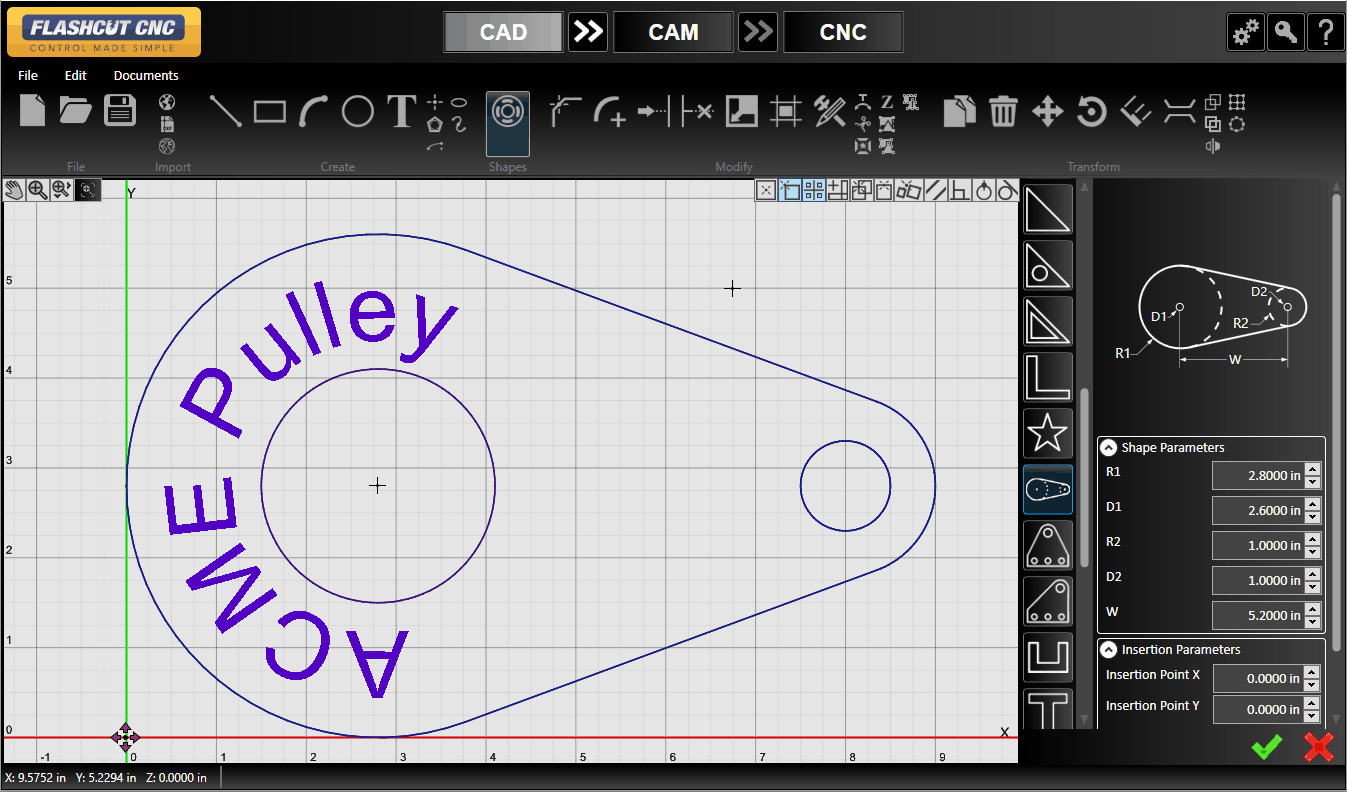

| Advanced Text (Includes True Type Font Support w/o Exploding and Curved Text Around Any Shapecadcam | × | × | × | × | × | ||||

| DXF Exportcadcam | × | × | × | × | × | ||||

| Part Shadingcadcam | × | × | × | × | |||||

| Marker Supportcadcamcnc | × | × | × | × | × | ||||

| Arc Fittingcad | × | × | × | × | |||||

| Bridge Entities Toolcad | × | × | × | × | × | ||||

| Fix Drawing Toolcad | × | × | × | × | × | ||||

| Multi Layer Color Image Importcad | × | × | × | ||||||

| Part Shadingcad | × | × | × | × | |||||

| Shape Librarycad | × | × | × | × | × | ||||

| Shape Welding Toolcad | × | × | × | × | × | ||||

| Advanced Lead-in Lead-out Editingcam | × | × | × | × | |||||

| Advanced Small Hole Processingcam | × | × | × | × | × | ||||

| Animated 3D Cutting Simulationcam | × | × | × | × | |||||

| Corner Loopingcam | × | × | × | × | |||||

| Fill Nest with Common Partcam | × | × | × | × | × | × | |||

| Free Cuttingcam | × | × | |||||||

| Import of parts from external filescam | × | × | × | × | |||||

| Multi-Sheet and Fill Sheet TrueShape Nestingcam | × | × | × | × | × | ||||

| Multiple Tabscam | × | × | × | ||||||

| Pattern Nestingcam | × | ||||||||

| Separate Pieces From Cutscam | × | ||||||||

| Skeleton Cuttingcam | × | ||||||||

| TrueShape Nestingcam | × | × | × | × | × | ||||

| Automatic Lead-In on Restartcnc | × | × | × | × | × | ||||

| Dynamic THC On/Offcnc | × | × | × | × | |||||

| Move to Point in Viewportcnc | × | × | × | × | × | ||||

| Progress Metercnc | × | × | × | × | × | ||||

| Puddle Jumpingcnc | × | ||||||||

| Rip Cuttingcnc | × | × | × | ||||||

| Smart Touch Offcnc | × | × | × | × | |||||

Additional Premium Features | FCS-10-CCC-PREM

+Quote

Loading…

| Premium 2D CAD/CAM/CNC Software | |||||||

| FCS-10-SMT360

+Quote

Loading…

| Smart360camcnc | × | × | × | |||||

| FCS-10-CHN_BRDG

+Quote

Loading…

| Chain and Bridge Cuttingcam | × | |||||||

| FCS-10-CA

+Quote

Loading…

| Collision Avoidancecam | × | × | × | |||||

| FCS-10-CL

+Quote

Loading…

| Common Line Cuttingcam | × | |||||||

| FCS-10-NEST_RPT

+Quote

Loading…

| Nesting Report + Part Numberscam | × | × | × | × | ||||

| FCS-10-AFM

+Quote

Loading…

| Advanced G-Code File Managementcnc | × | × | × | × | × | |||

PREM + REM | FCS-10-CCC-PREM-REM

+Quote

Loading…

| Premium + Remnant 2D CAD/CAM/CNC Software | |||||||

| FCS-10-REMNANT

+Quote

Loading…

| Remnant Support | × | |||||||

A-La-Carte Add-On Features | A-La-Carte Add-On Features | ||||||||

| Advanced Drilling (Included with Pro 2.5/3D CAD/CAM)camcnc | × | ||||||||

| FCS-10-LASER

+Quote

Loading…

| Advanced Laser Cutting Supportcamcnc | × | × | × | |||||

| FCS-10-WJ

+Quote

Loading…

| Advanced Waterjet Supportcamcnc | × | × | × | × | ||||

| FCS-10-CNC-LASER | Basic Laser Cutting Supportcamcnc | × | × | × | |||||

| FCS-10-CNC-WJ | Basic Waterjet Supportcamcnc | × | × | × | × | ||||

| FCS-10-PIPE-BEVEL

+Quote

Loading…

| Bevel Round Pipe Cutting with Dual-Rotary CNCcamcnc | × | × | ||||||

| FCS-10-HPR

+Quote

Loading…

| HPR Auto-Gas Controlcamcnc | × | × | × | |||||

| FCS-10-KJHD | Kjellberg Smart Focus and Hi-Focus Auto Gas Supportcamcnc | × | × | ||||||

| FCS-10-KNIFE

+Quote

Loading…

| Knife Cutting Supportcamcnc | × | × | ||||||

| FCS-10-CNC-ROTARY

+Quote

Loading…

| Rotary Axis Supportcamcnc | × | × | × | × | ||||

| Laser Stitching Support (Included with Laser)camcnc | × | × | |||||||

| FCS-10-ROUTER

+Quote

Loading…

| Mill, Drill and Router Supportcamcnc | × | × | × | |||||

| FCS-10-MULTI_FH | Multiple Simultaneous Fabheadscamcnc | × | × | × | × | × | |||

| FCS-10-PIPE-RECT

+Quote

Loading…

| Rectangular Tube Cutting (add-on to Round Pipe)camcnc | × | × | ||||||

| FCS-10-PIPE-ROUND

+Quote

Loading…

| Round Pipe Cutting with Rotary CNCcamcnc | × | × | × | |||||

| FCS-10-XPR

+Quote

Loading…

| XPR Auto Gas Support camcnc | × | × | ||||||

| FCS-10-LPS-35 | Laser Pointer Software and Hardware w/ 35′ Cablecnc | × | × | × | × | ||||

| FCS-10-LPS

+Quote

Loading…

| Laser Pointer Software Onlycnc | × | × | × | × | ||||

| FCS-10-ATC

+Quote

Loading…

| Auto Tool Change Supportcnc | × | × | ||||||

| FCS-10-DVZ

+Quote

Loading…

| Dynamic Ventilationcnc | × | × | × | × | × | |||

| FCS-10-COM-HD-422 | Hi-Definition Plasma Communications Sfw and Hdw (RS422) (Must be used in conjunction with Auto Gas Support)cnc | × | × | × | |||||

| FCS-10-COM-MP200-422

+Quote

Loading…

| MAXPRO 200 Plasma Communications Sfw and Hdw (RS422) cnc | × | |||||||

| FCS-10-TS | Motor Current Sensingcnc | × | × | × | |||||

| FCS-10-COM-PM-485

+Quote

Loading…

| Powermax Plasma Communications Sfw and Hdw (RS485) w/ Live SYNC Cartridge Usage Reportingcnc | × | × | × | × | ||||

| FCS-10-THC-35

+Quote

Loading…

| THC Sfw and Hdw w/ 35′ Cablecnc | × | × | × | × | × | × | ||

| FCS-10-LPS

+Quote

Loading…

| Workpiece Alignment (Included with laser pointer)cnc | × | × | × | × | × | |||

- Standard CAD/CAM/CNC – Includes enough features to easily draw or import parts in CAD, make efficient tool paths in CAM and cut parts accurately in CNC

- Pro CAD/CAM/CNC – Everything in the Standard version plus many other features for the professional such as shading and multi-layer management in CAD, True-Shape Nesting and advanced lead-in management in CAM, and auto lead-in on restart in CNC to name a few.

- A-la-carte features – Special features for demanding applications such as Smart360 hole cutting technology and dynamic vent zones. Also includes targeted features that are only included in application specific versions such as water jet, laser and HPR plasma.