Software Features

STD

PRO

ALC

Title

STD

PRO

ALC

Title

STD

PRO

ALC

Title

STD

PRO

ALC

Title

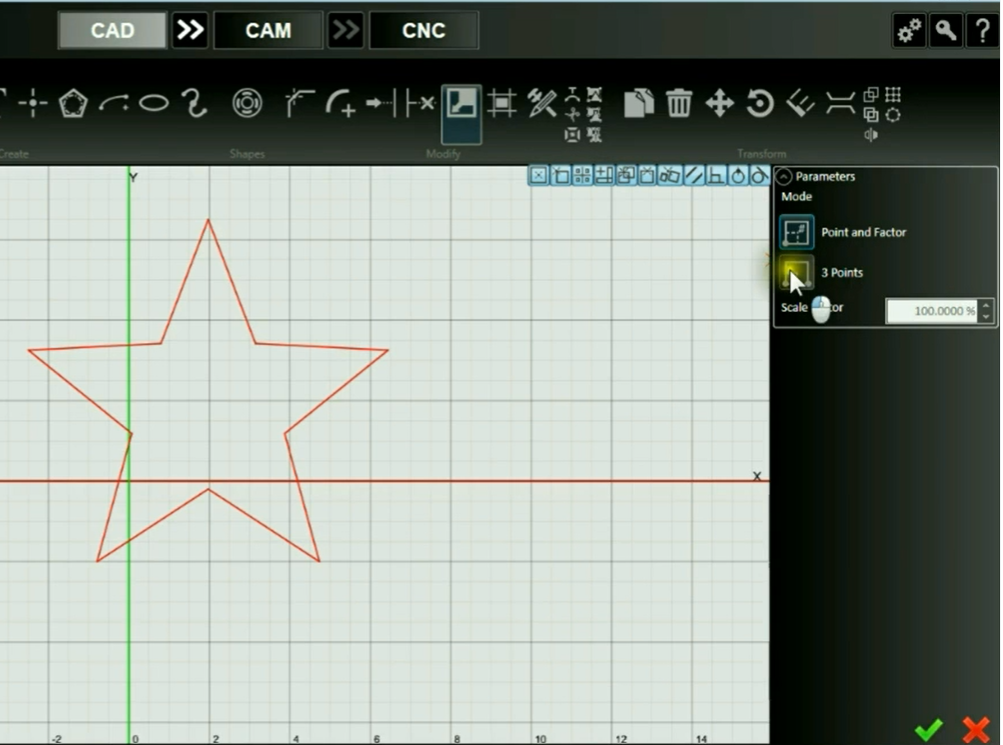

Scale and Offset

Introduced in: Version 5

Easily scale the size or offset the geometry of an entity.