CNC Plasma Controllers

World-class CNC plasma software to power up your cutting technology.

Cut with a World Leader for Integrated CNC Plasma Controllers and CAD/CAM Software

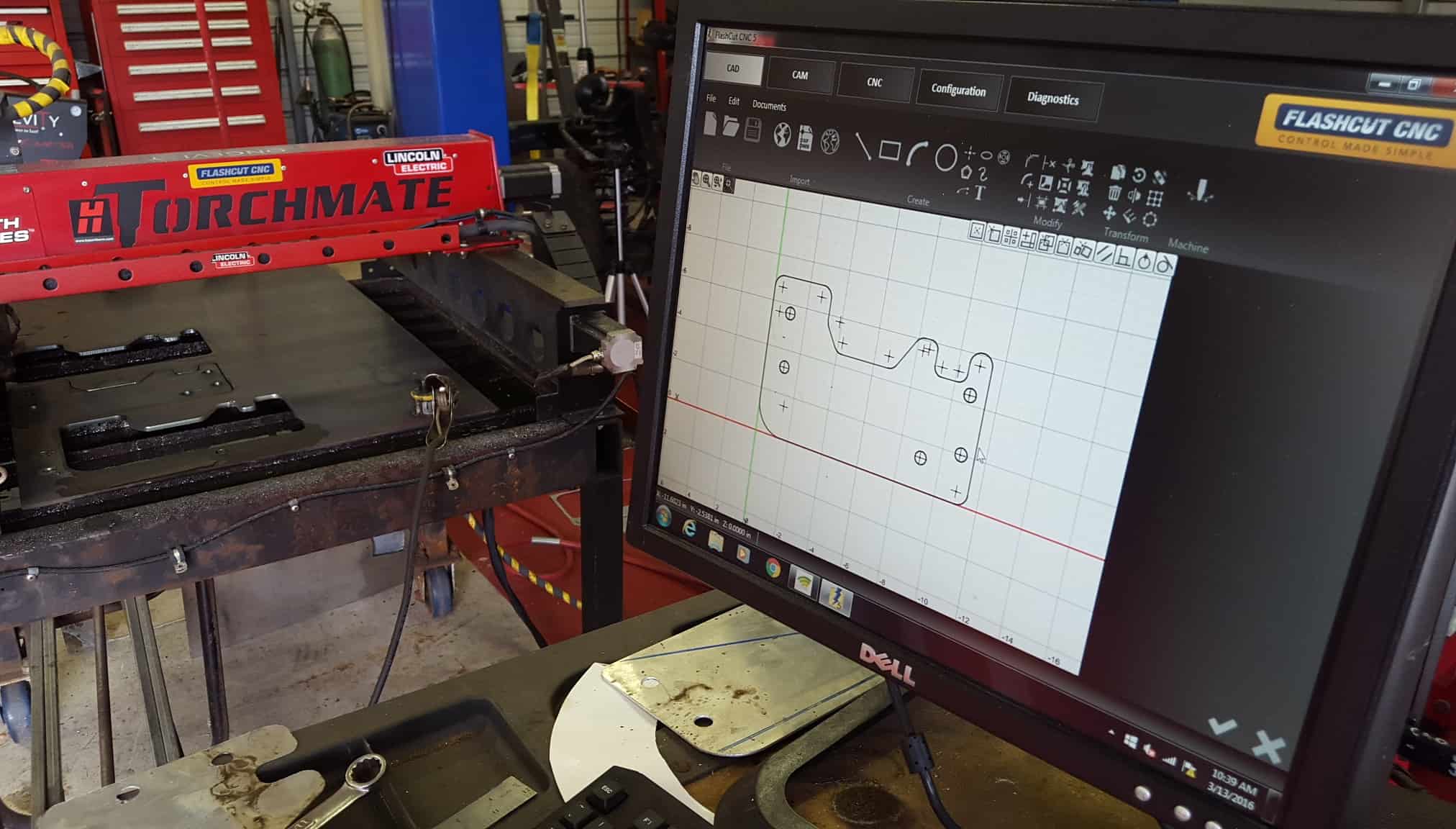

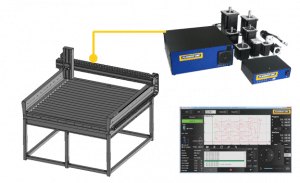

Our world-class CAD/CAM nesting software and CNC plasma controller kits are among the most widely used in the plasma cutting industry. Our products can be easily tailored to drive your CNC plasma table as if they were made for each other. Whether you are building a new table, upgrading, or retrofitting an existing one, we have the right CNC plasma cutter software solution for you. FlashCut CNC plasma controllers can provide turn-key controls for any size plasma machine from our complete line of digital stepper or servo controls and motors. Decades of experience, superior features and tens of thousands of satisfied customers world-wide make FlashCut’s fully integrated CAD/CAM/CNC plasma control system among the best in the world.

Features of our CAD/CAM nesting and CNC plasma control system:

- Powerful CNC plasma CAD software with intuitive, and comprehensive drawing tools

- Automated CNC plasma CAM software with true-shape nesting and smart placement of lead-ins and lead-outs

- Integrated Stingray® CNC plasma cutter torch height control

- Our CNC plasma cutter controller wizard automatically sets THC parameters based on material, thickness and consumables

- Support for all leading brands such as Hypertherm’s® Powermax®, MaxPro®, XPR® and HPR® series, Kjellberg’s® Smart Focus®, HiFocus® and Q® along with Thermal Dynamics® AutoCut®, CutMaster®, and UltraCut® and more.

- Automatic kerf crossing detection prevents unwanted diving during THC operation.

- Communication with Hypertherm Powermax units for real-time amperage and pressure control.

- Auto Gas support for Hypertherm and Kjellberg high-definition plasmas.

- Support for multiple plate sensing technologies such as ohmic and pressure sensing

- Smart 360™ hole cutting technology for cutting the truest holes in the industry – even with air plasma.

- Intuitive CNC plasma control panel

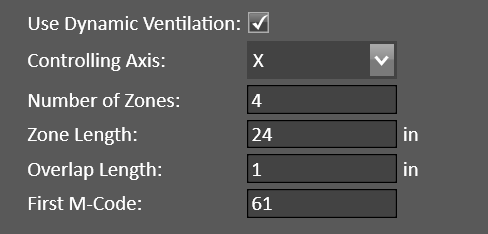

- Automated vent zones

CNC plasma control system technology

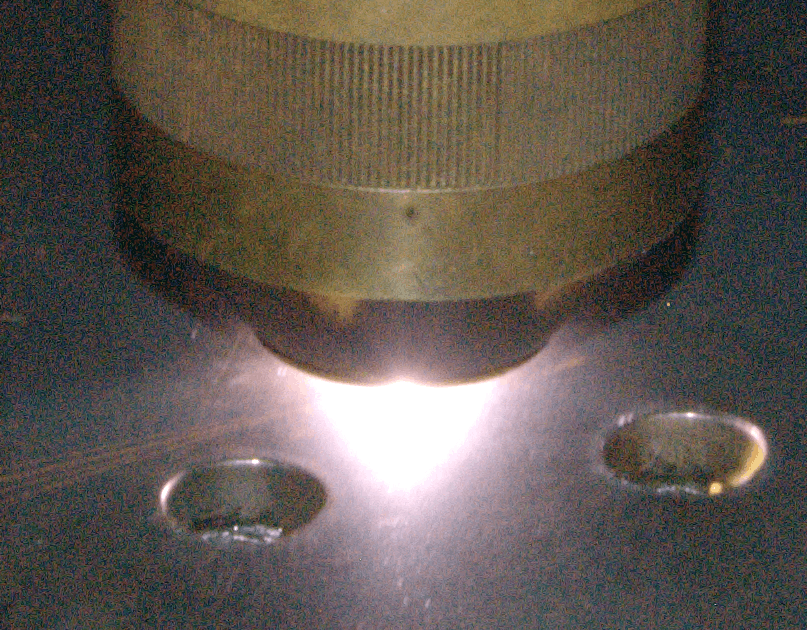

CNC plasma cutting uses a high-temperature, electrically conductive gas (plasma) to almost instantaneously melt metal sheets. A high-pressure localized gas stream is used to evacuate the molten zone to cut through the metal sheet. The CNC plasma cutter controller is suitable for ferrous and non-ferrous materials and can also handle metal in any condition – even rusted, painted, or grated. Air plasma cutters typically cut metals ranging from thin gauge and 1.5″ (40mm) in thickness. High-definition plasma tables use other gases and can use very high amperage levels to cut through much thicker material – in some cases from 4-6″ (200-250mm) thick. Plasma’s ability to cut quickly and precisely makes it an excellent CNC cutting system.

Technologies such as FlashCut’s Stingray® Torch Height Control can maintain a very close gap while cutting to create very accurate parts. FlashCut CNC’s Smart 360 technology is an excellent way to diminish the bevel significantly and maximize accuracy on bolt holes. With some torches, plasma amperage levels can be turned down, and gas mixtures can be optimized to do CNC engraving and marking.

Advantages of CNC Plasma Cutting

- Cuts a wide variety of metals including mild steel, aluminum, stainless steel, and cast iron

- Delivers accuracy better than 0.008″

- Impressive hole quality with Smart360 Technology

- Economical

- Fast cutting speeds

- Can cut corrugated material using Stingray Torch Height Control

- The best CNC plasma controller software by FlashCut is tailor-made for your needs, budget, and application.

We also offer the best CNC solutions for other 3D and 2D cutting technologies such as NC oxy-fuel cutting, CNC water jet cutting, CNC laser cutting,CNC router cutting and much more.

Our CNC plasma controller kits are powerful, precise, and intuitive. See what our all-in-one integrated program can do for all your drawing, toolpath, and cutting needs.

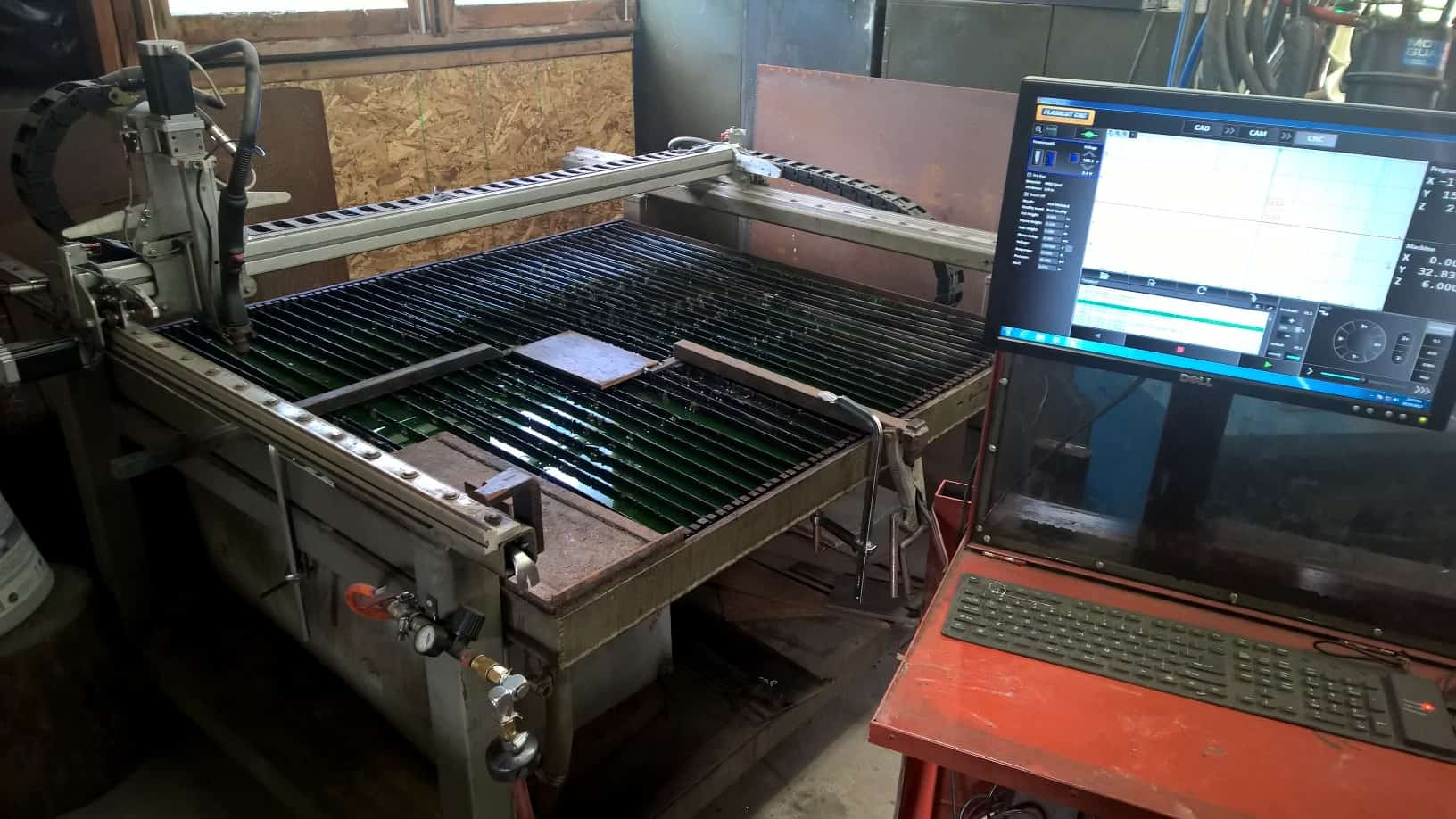

FlashCut CNC Plasma Retrofits

Breathe new life into your existing Plasma Table. FlashCut CNC Plasma retrofits are simple and powerful. In most cases, you will be up and running within a day with the latest and greatest integrated FlashCut CAD/CAM/CNC and torch height control technology.

Retrofits save you time and money with more productivity and less maintenance making a CNC plasma retrofit very economical.

We have successfully upgraded thousands of machines like Torchmate®, C&G®, Messer®, Koike®, Lockformer®, MultiCAM®, Vicon®, EZ-Cut®, Baileigh®, Dynatorch® and machines from many other CNC plasma manufactures.

Whether their machine was brand new or older, these machine owners saw the value of a FlashCut upgrade to replace the software and controls originally supplied by Burney®, Promotion®, and Hypertherm®, to name a few.

Key features of FlashCut Retrofits

- Our CNC retrofit kits are simple and powerful

- Applications range from plasma, waterjet, and laser to oxyfuel, router, mill, and lathe cutting tables

- Get up and running within a day

- Upgrade your machinery with our latest and greatest CAD/CAM/CNC plasma retrofit kits

- Get application-specific features like Stingray Torch Height Control, Smart360 or advanced cornering technology, and more

- Save time and money, and become more productive with our economical solutions

Our retrofits have brought new life to many different types of plasma machines by replacing old software and controls with new and improved FlashCut technologies.

Powerful CNC Plasma Controller Tailored for Your Table

We have decades of experience in matching one of our precision CNC plasma control systems to your plasma table – including CNC controls, motors, and cables. Whether you are doing light industrial or heavy production, our complete line of state-of-the-art micro stepper and closed-loop servo controls and motors will drive your machine with precision, power, and ease.

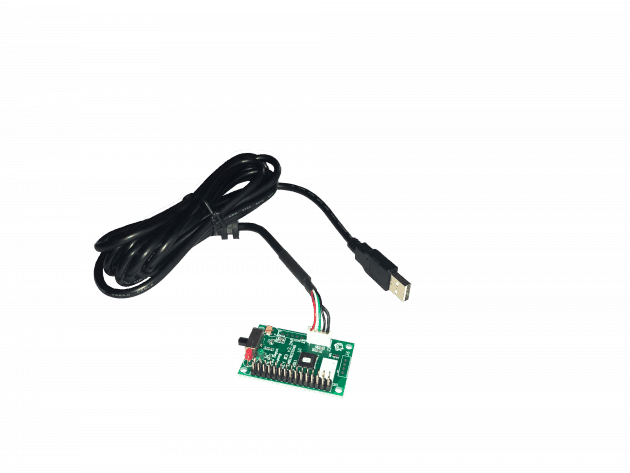

Our plug-and-play CNC plasma controller kits are built to give you higher efficiency and flexibility when operating your machine. With a simple Windows-USB connectivity, you can control your machinery in real time through our CNC controls & software, giving you both microsecond-level control and an intuitive graphical interface.

We are able to call ourselves leaders in the game thanks to our secret ingredient – our USB signal generator. 3 microprocessors handle parallel processing for our 5-axis simultaneous motion, giving you ultimate control and super smooth motion.

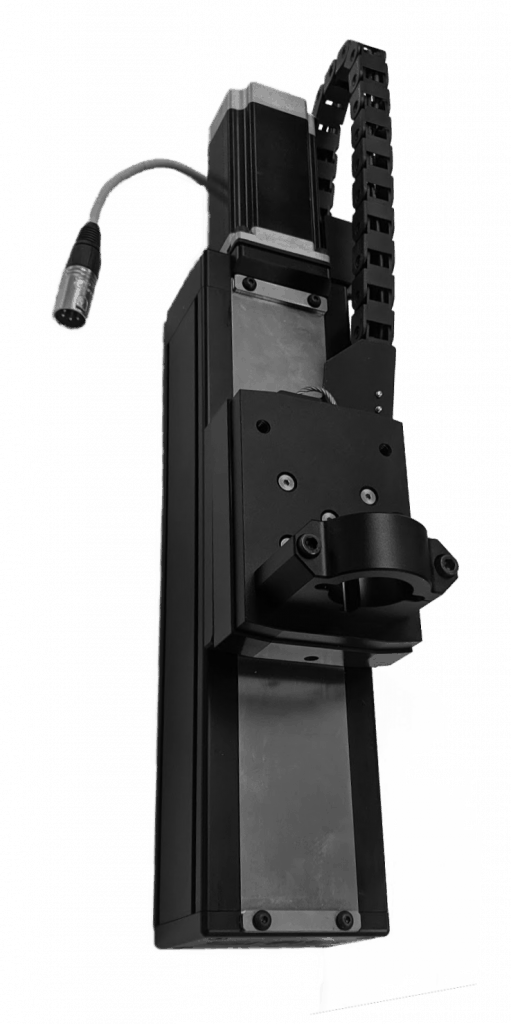

Stingray® Torch Height Control

FlashCut’s Stingray Integrated THC reads the plasma voltage as feedback to adjust the Z-axis height thousands of times a second. This system maintains a precise distance between the plasma torch and the workpiece while cutting any XY pattern at any speed, resulting in smooth edges, sharp details, and higher precision. The system can inherently handle warped, bent, or corrugated sheets.

There are many advantages to integrating the Stingray® THC with the XYZ movement, including:

- No duplication of Z-axis CNC plasma motion control, saving thousands of dollars over using two control systems

- Real-time visualization of plasma voltage, height and position parameters in the best CNC plasma software interface

- Advanced diagnostics lets you visualize THC performance via historical charts of voltage and height

- Precision voltage sampling ensures tracking at the optimal height on every cut, day after day

- Optimal control and tracking of nozzle use leads to better consumable life and cut quality

- Cut wizard automatically sets THC parameters based on material, thickness and consumables for all of the major plasma machines including Hypertherm®, Thermal Dynamics®, and Kjellberg®

- Automatic kerf crossing detection prevents unwanted diving during THC operation

- Real-time THC control during feedrate changes to prevent unwanted material diving

- RS-485 Communications with Hypertherm Powermax® units for real-time amperage and pressure control

- Support for multiple plate sensing technologies such as ohmic, mechanical switch and servo pressure sensing

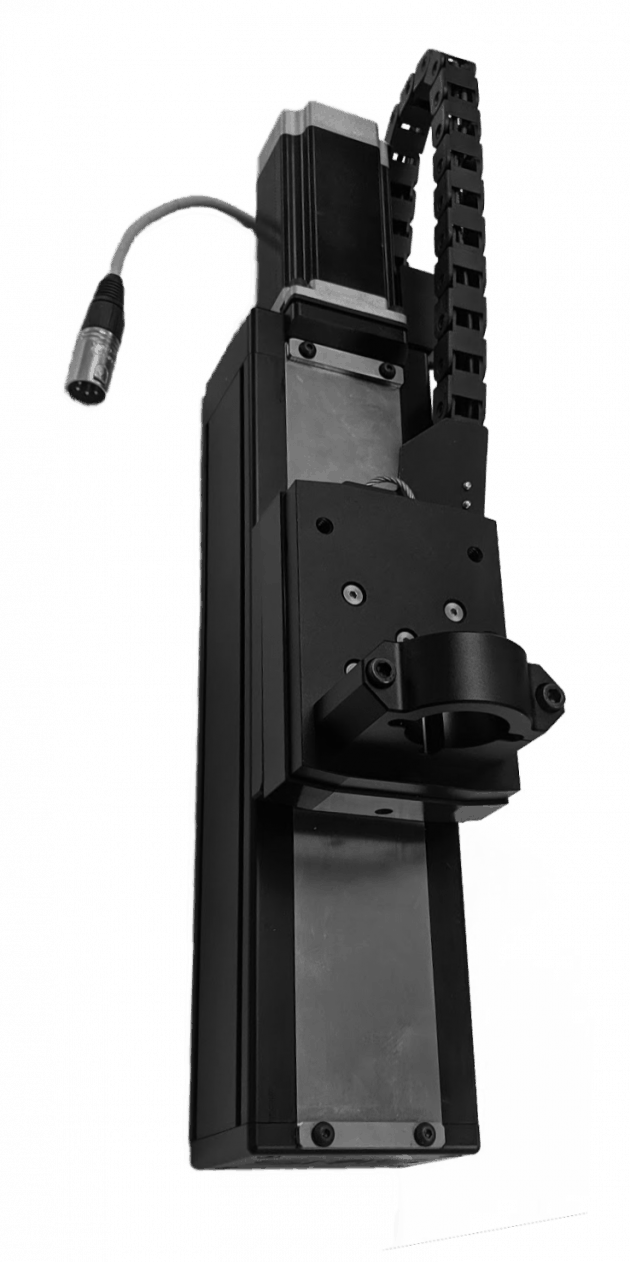

- Precision lifter available featuring precision ball-screw drive, linear rails, stainless steel sealing, and magnetic breakaway

- Ohmic Disconnect is available for the ultimate noise reduction of high frequency and high power plasma machines.

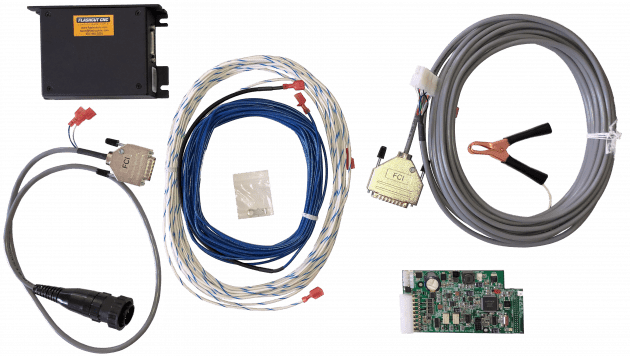

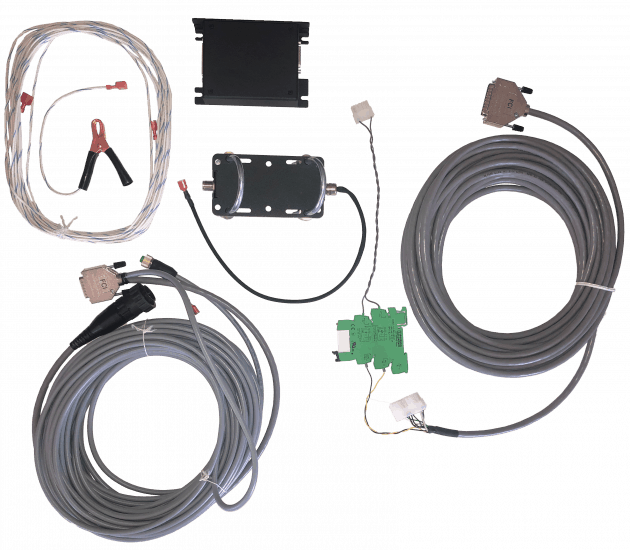

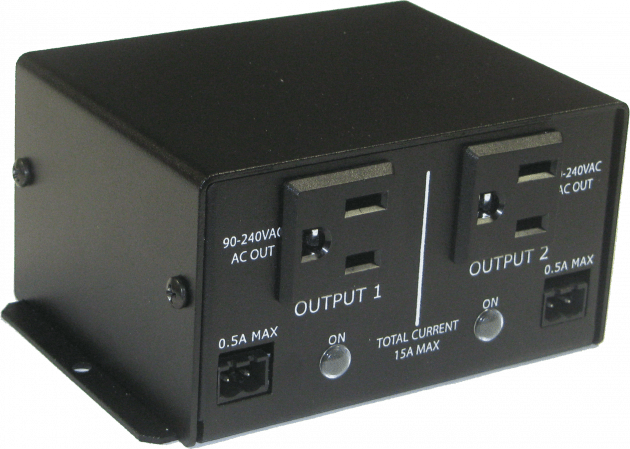

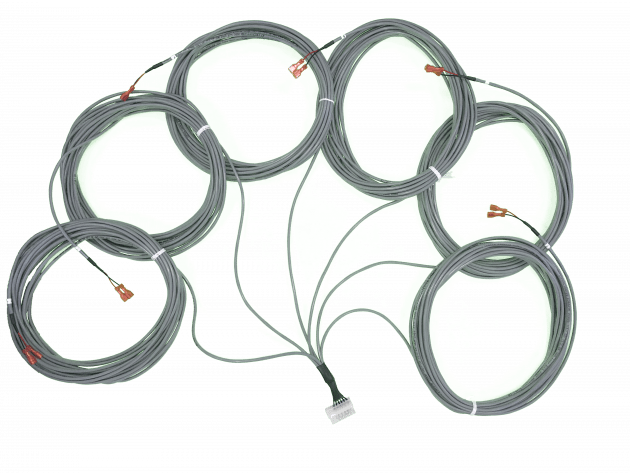

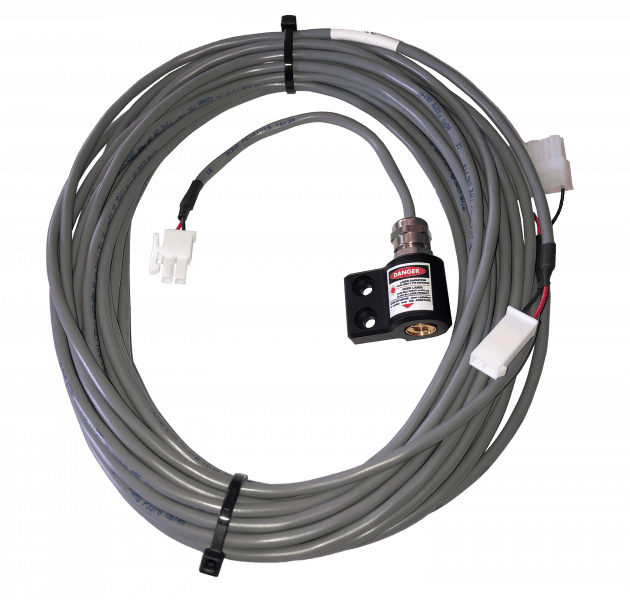

The Stingray THC system can be added to any new controller, or it can be retrofitted to all existing Compact, Pro-Series, or Titanium controllers using FlashCut’s unique technology. The THC kit can be configured using any of the following components for plug-and-play operation with your CNC plasma table controller:

- Analog controller card

- Voltage isolation box

- All necessary cables

- Optional ohmic disconnect for hi-def plasma

- Optional mechanical lifter with torch holder with magnetic breakaway

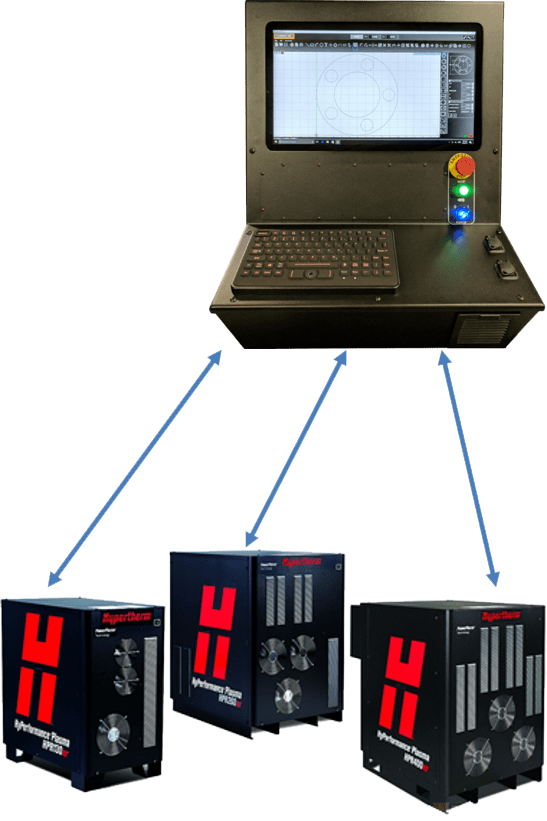

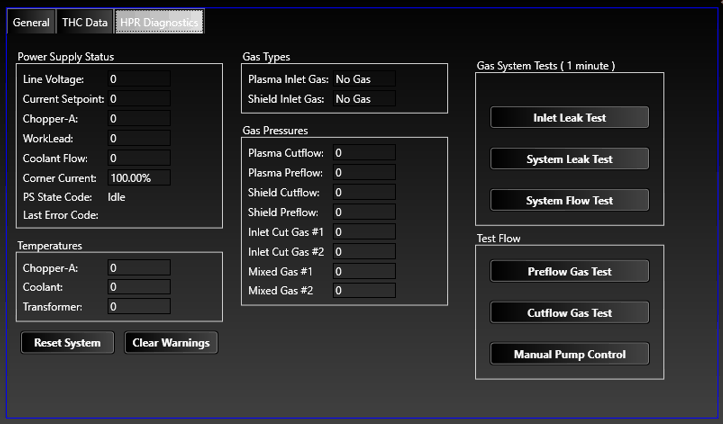

Full Support for Hypertherm XPR, HPR, MAXPRO200 and Kjellberg Smart Focus and HiFocus high definition plasma systems

Now you can use FlashCut’s intuitive, powerful, and integrated CAD/CAM/CNC plasma software interface to control Hypertherm® XPR®, HPR®, MAXPRO200® plasma systems and Kjellberg® Smart Focus® and HiFocus® high definition plasmas. The intuitive interface has been engineered to give you seamless access to all of the controls, commands, and messages so that you can cut precision parts with high definition plasma quickly and easily. Our new Smart360 HCT has been engineered to cut the highest precision holes for any given gas mixture.

We now have full EtherCAT support for the Hypertherm XPR and the Kjellberg Q so you can take full advantage of all settings and diagnostics on the fly in our world famous graphical interface.

- Full EtherCAT support for XPR 170 and 300 plasma systems

- Supports HPR 130, 260, 400, 800 plasma systems

- Supports MAXPRO 200 plasma system

- Full EtherCAT support for Kjellberg Q

- Supports entire Kjellberg Smart Focus and High Focus plasma systems

- RS-422 connection provides seamless communication between the FlashCut interface and high definition plasma machine

- Auto-gas control for mixing the plasma and shield gases

- GUI control of amperage and pressure

- Separate amperage settings for ramping and full speed cutting

- Seamlessly change from marking to cutting settings on the fly

- Integrated cut charts

- Precision height control using FlashCut’s Stingray® THC

- Ohmic disconnect circuitry protects the system from noise and voltage spikes

- Compatible with FlashCut Pro-Series and Titanium Controllers

- Real-time diagnostics shows torch status and history of error messages and important parameters

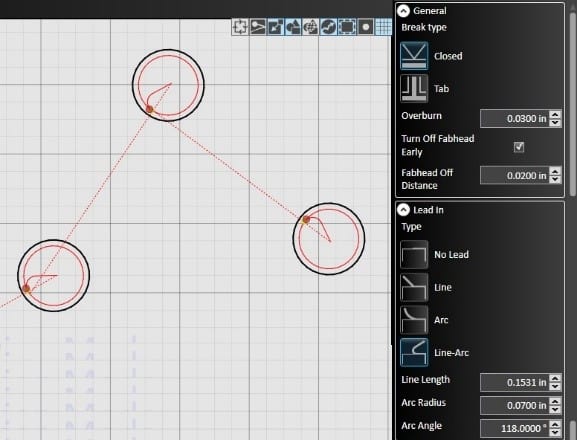

Smart360™ Hole Cutting Technology for Air and Hi-Def Plasma

FlashCut’s exclusive Smart360™ Hole Cutting Technology produces excellent quality holes and cutouts:

- Works with all plasma systems cutting mild steel including air plasmas and high definition plasmas

- Auto-recognition of small holes utilizes lower feed rates and temporarily turns off THC to prevent diving

- Auto-calculation of kerf vs. federate creates high accuracy holes

- Early torch turn-off prevents extraneous marks at the end of the hole

- Line-arc lead-in reduces mark at the beginning of the hole and ensures a uniform feed rate along with the entire cutout

- Can be used to increase the accuracy of small cutouts in addition to round holes

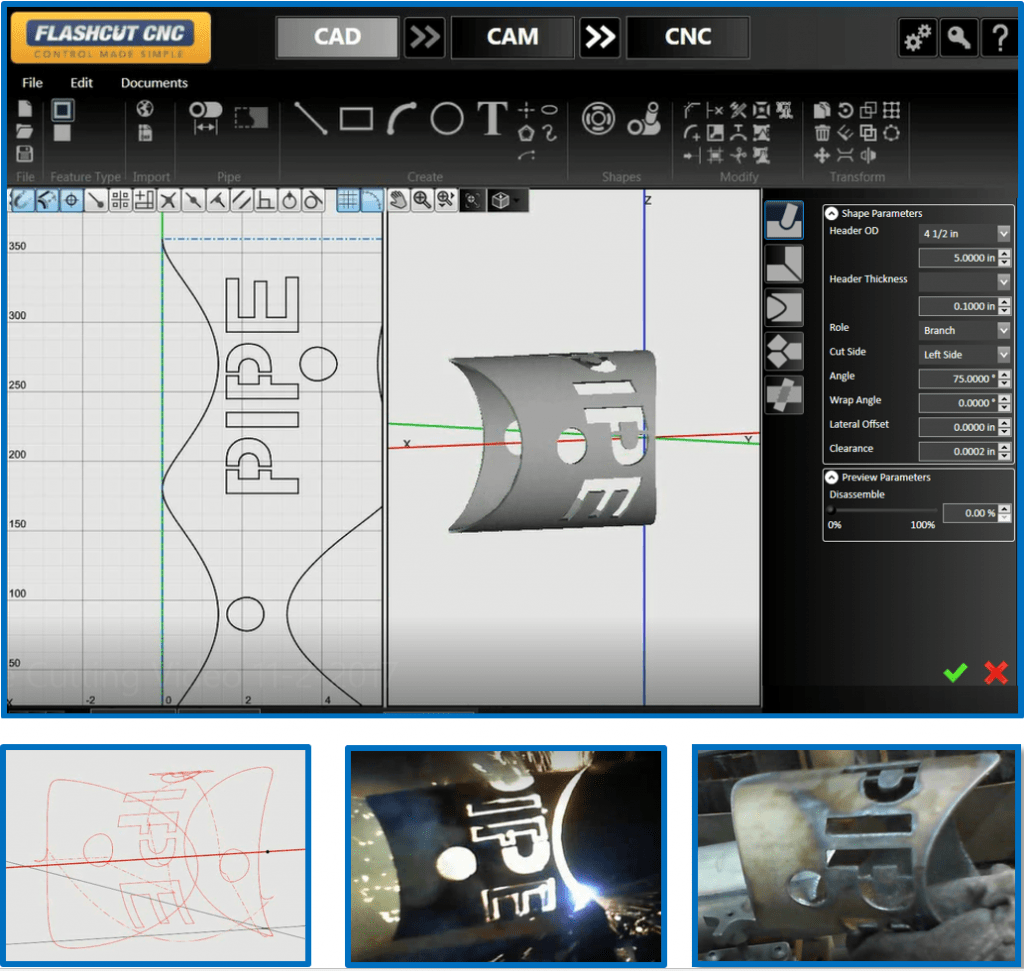

Pipe Cutting CAD/CAM/CNC software for round pipes and rectangular tubes

Easily Draw Accurate Pipe Features in CAD

- Round pipe, square and rectangular tube support

- Pipe shape wizard makes perfect cuts for mating pipes of any diameter with a multitude of joints at any angle and any size including T joints, end caps, miter joints, Y joints and through pipes

- Pipe sizing wizard automatically sets OD, and thickness of standard pipe sizes

- 3D solid model of pipe joints includes disassembly to preview what both sides of the joint will look like

- The flattened view allows for easy design of custom patters of any shape including slots and text

- “Ghost 2D views” show feature wrapping with no interruption

- Fully rotatable solid model view

- Easily import DXF and STL files from other CAD programs

- Best CAD software for CNC plasma

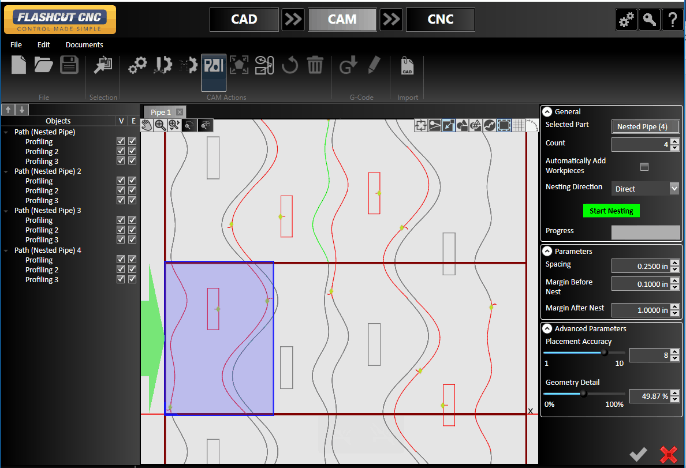

Tailor Toolpaths and Nest in a Snap with CAM

- Easily nest multiples of the same or different parts, minimizing pipe or tube scrap

- Toolpath automatically generated in CAM using parameters and cut charts from cutting head

- Simple graphical manipulation of lead-ins and lead-outs

- Embedded cut charts precisely set feedrates, cut heights, pierce times, kerf compensation and target voltages for any size pipe

Cut Accurate Parts With Confidence in CNC

- G-Code automatically generated

- Full 3D visualization of rotary toolpath in CNC module while the pipe is being cut

- Flat sheet option for cutting unwrapped pipes and tubes

- No-Cut zones account for chuck, fixture and roller locations – preventing roller burning or jamming

- Stingray® Torch Height Control ensures clean cuts regardless of the accuracy of the stock pipe

Precision bevel cutting for round pipe

- Our pipe cutting CAD/CAM/CNC software achieves precise angles for beveled edges

- Expertly programmed CNC pipe cutting software systems from FlashCut ensure consistent and precise cuts

- Suitable for bevel cutting metal, plastic, composite, and even concrete round pipes

- Create a variety of bevel angles to meet your specific needs

CNC Plasma Control System Accessories

Our CNC plasma controllers can be enhanced to fit your needs with our control system accessories. From control functions such as joystick jogging to an easier connection to your input device, we have it all. Pick and choose the accessory you need to optimize on the features & benefits of your existing systems.

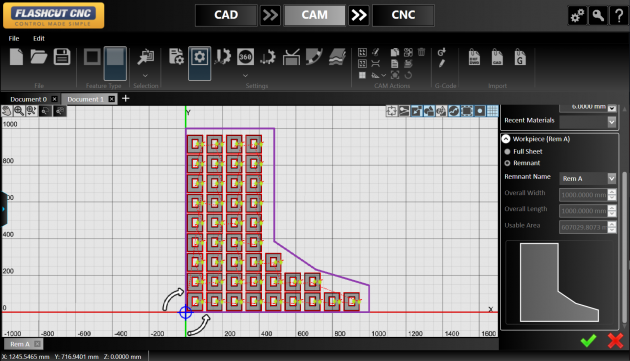

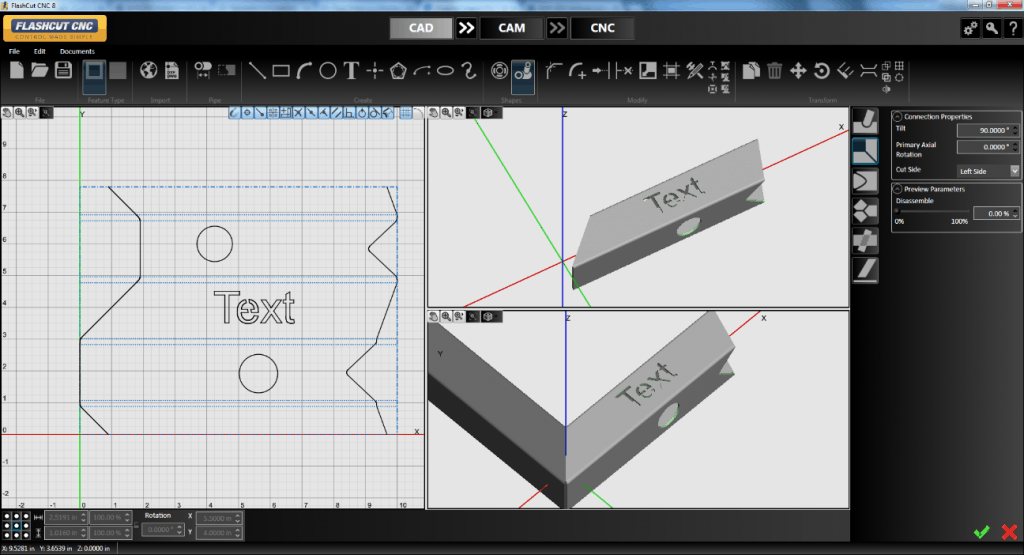

2D Plasma CAD/CAM Software

Go from Drawing to Toolpath to Cutting all in one Integrated CAD/CAM/CNC Plasma Software. Going from CAD to CAM to CNC has never been easier.

We now have two packages to choose from:

- The Standard CAD/CAM makes it easy to draw a part or import it from DXF or an image and then turn it into a tool path with intelligently placed lead-ins and the perfect kerf compensation… ready to cut in CNC.

- The Pro adds many features such as shape library, true shape nesting, multi-sheet nesting, multi-layer color import, auto-fix tool, advanced lead-in

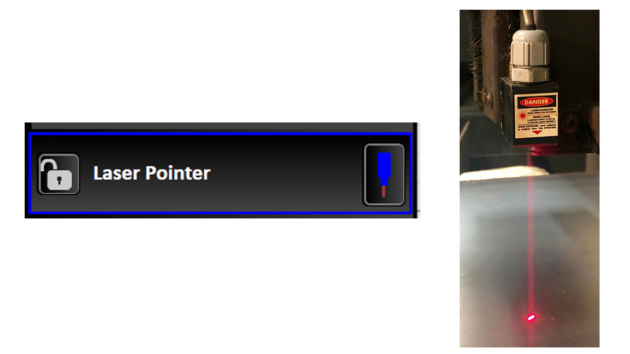

manipulation, rip cutting, and many more features. - Other features such as laser pointer, plate alignment, nest report, advanced g-code management, collision avoidance and many more can be added on an a-la-carte basis.

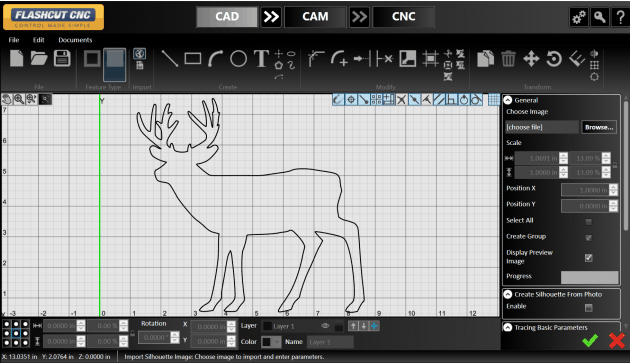

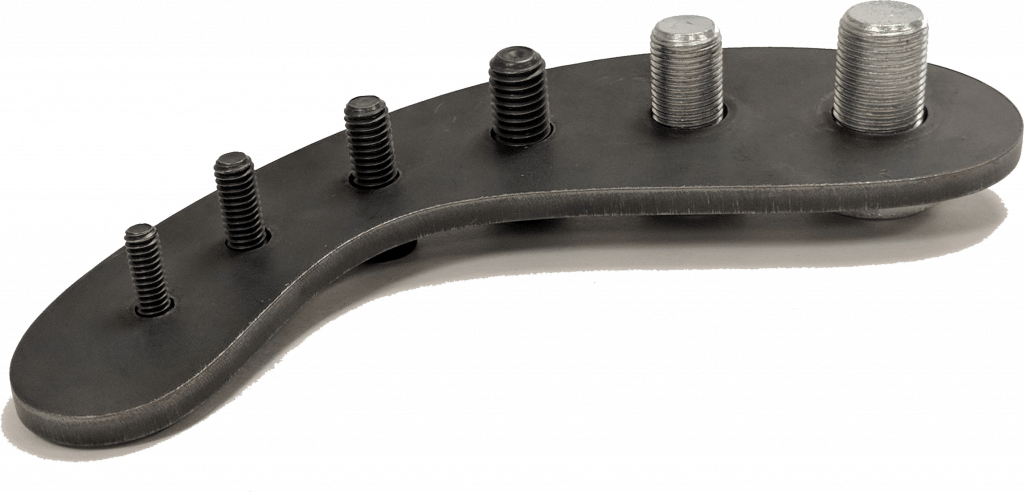

Customer Projects made with FlashCut’s CAD/CAM and CNC Controls

FlashCut’s CNC Plasma Control systems have the power and precision to cut a wide range of metal shapes into intricate designs. Here are some projects our customers were able to bring to life with our Plasma CNC Software.

Frequently Asked Questions About Plasma CNC Controllers

What are the differences between CNC for plasma and water jet controllers?

The difference between CNC plasma cutting software and CNC water jet controllers lies in the cutting methods and the hardware used, such as the cutting head and the power source. CNC plasma table controllers are crafted for high temperature cutting designated for specific metals. Water jet controllers are high-pressure systems for cutting a wider range of metals.

How accurate are FlashCut CNC plasma controllers?

FlashCut CNC plasma controllers are tailor made with a higher degree of precision, usually within a few thousandths of an inch. Our systems are optimized to deliver fine-tuned results. Nevertheless, accuracy may vary due to factors like machine setup, calibration, and the quality of the components used.

How long does it take to deliver the FlashCut CNC plasma controller?

All goods that are in stock and do not require assembly or rework may be shipped to you within 5 business days. Products that are not in stock will be shipped according to our production schedule. Don’t hesitate to get in touch if you want to learn more about our delivery dates and other specifics.

What are the limitations of the CNC plasma controller?

Due to its nature, the plasma controller CNC may be limited in cutting thicker materials that require other cutting methods. Other limitations may include the need for proper ventilation, and challenges in achieving intricate shapes.

How much does a FlashCut CNC plasma controller cost?

The price of our CNC plasma controller software can vary significantly due to the model and specific features your operation requires. For an accurate quote, please get in touch with us or use our quote builder.

Does FlashCut offer training on operating the CNC plasma controller?

Your success is vital to all of us here at FlashCut. That’s why we house a massive online knowledge base of manuals, video literature, and other product literature to help you achieve the best results.