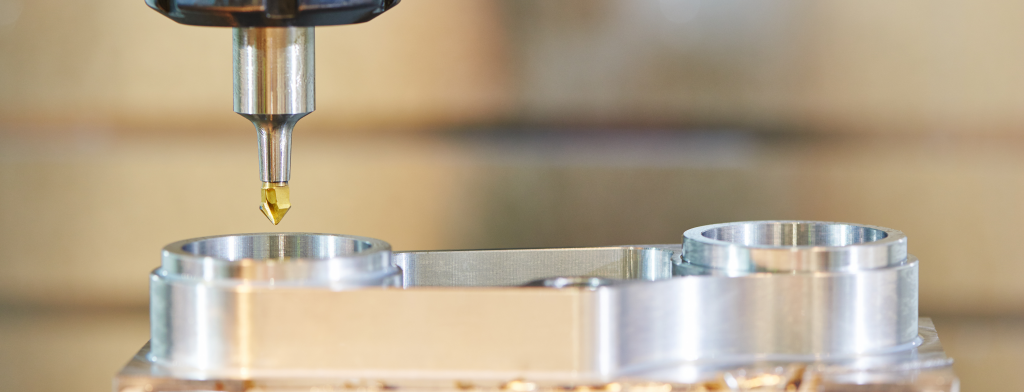

Milling

Overview

CNC Mill Kits and CNC Mill Controllers

FlashCut CNC precision controls for vertical mills and machining centers with up to 5 axis simultaneous motion control. Perfect for any size mill from miniature mills to large Bridgeport type mills. Optional 4th axis and 5th axis rotary table support, auto tool change support, spindle speed support, coolant support, vacuum support and much more.

Controls

Powerful CNC Mill Controllers Tailored for Your Machine

FlashCut CNC precision controls for vertical mills and machining centers with up to 5 axis simultaneous motion control. Whether you are doing light industrial or heavy production our complete line of state of the art microstepper and closed-loop servo controls motors will drive your machine with precision, power and ease.

Accessories

Part Number

Part Name

Description

Image

+Quote

Loading...

8 Channel Relay Board with cable for connection to Signal Generator Board...

+Quote

Loading...

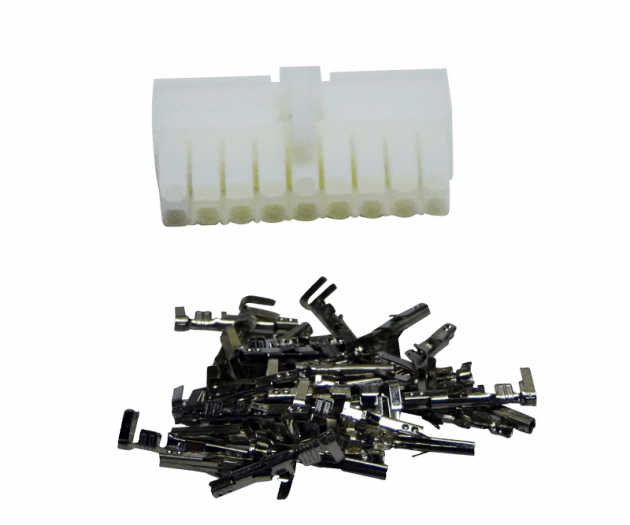

I/O Connector Kit for Mini I/O Expansion Board includes 18 pin MFJ connector and contacts...

+Quote

Loading...

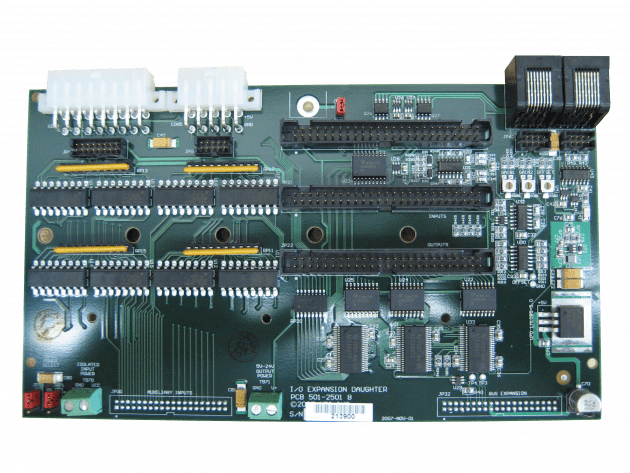

Adds 24 inputs, 24 outputs, analog ins and outs to Signal Generator and Pro Series Control...

+Quote

Loading...

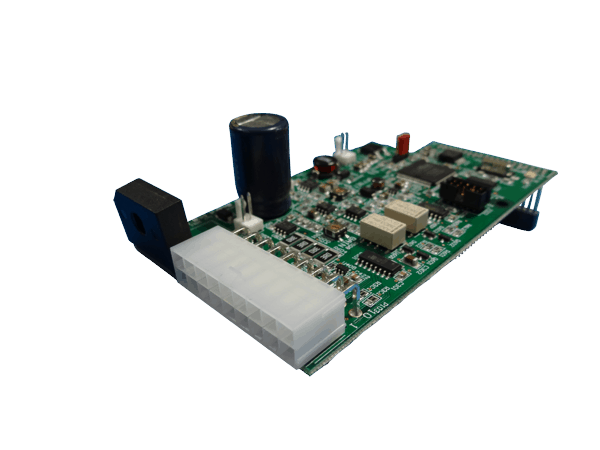

Easily adds 1 analog, 1 PWM & 2 relay outputs, 1 analog & 1 quadrature encoder or ...

+Quote

Loading...

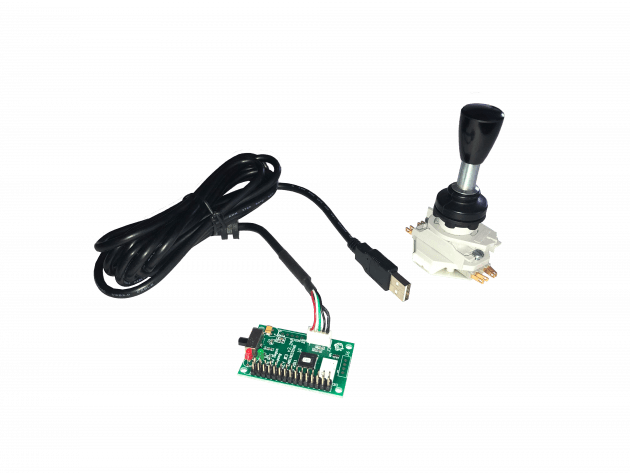

24-function and 8-direction joystick pendant with programmable functions such as jogging a...

+Quote

Loading...

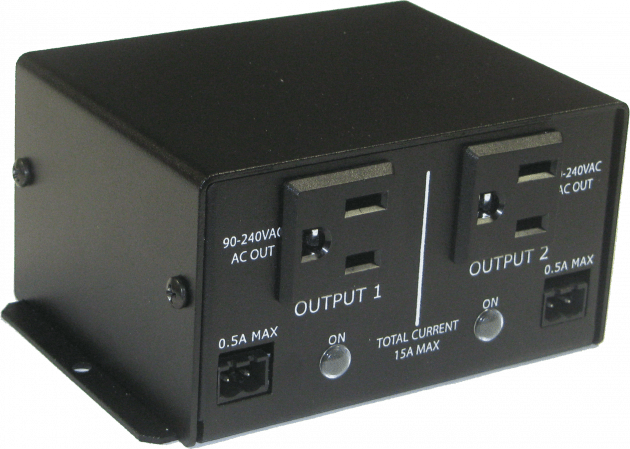

Convenient metal enclosure with 2 switched 110-240 VAC relays and 2 contact relays...

+Quote

Loading...

10' cable harness for 5 input lines. Switches not included....

+Quote

Loading...

Set of 5 industrial switches for rugged limit or home input lines. ...

+Quote

Loading...

8 position joystick for jogging in the XY plane including 45 degree angles....

+Quote

Loading...

Programmable matrix board that allows you to add up to 144 physical switches to your contr...

Software

Part Number

Part Name

Description

Image

+Quote

Loading...

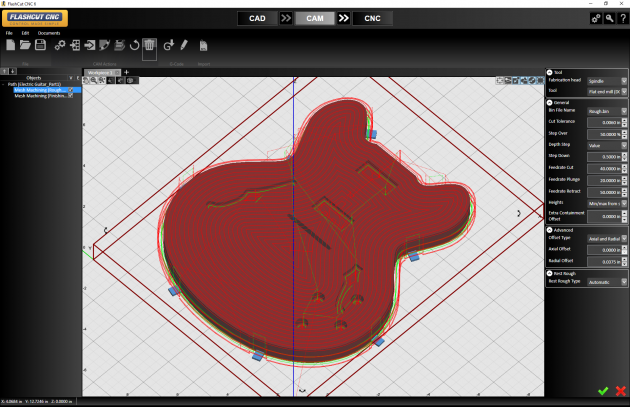

The world's easiest to use 2.5D CAD and 3D CAM for milling and routing applications....

+Quote

Loading...

Support for most auto tool changers for mills and routers including linear rack and rotary...

+Quote

Loading...

Adds the ability to control a full functioning rotary axis to your CNC machine....