Go From Drawing to Toolpath to

Robotic Plasma Cutting in a Flash

Take plasma cutting to the next level with a world leader in plasma CNC

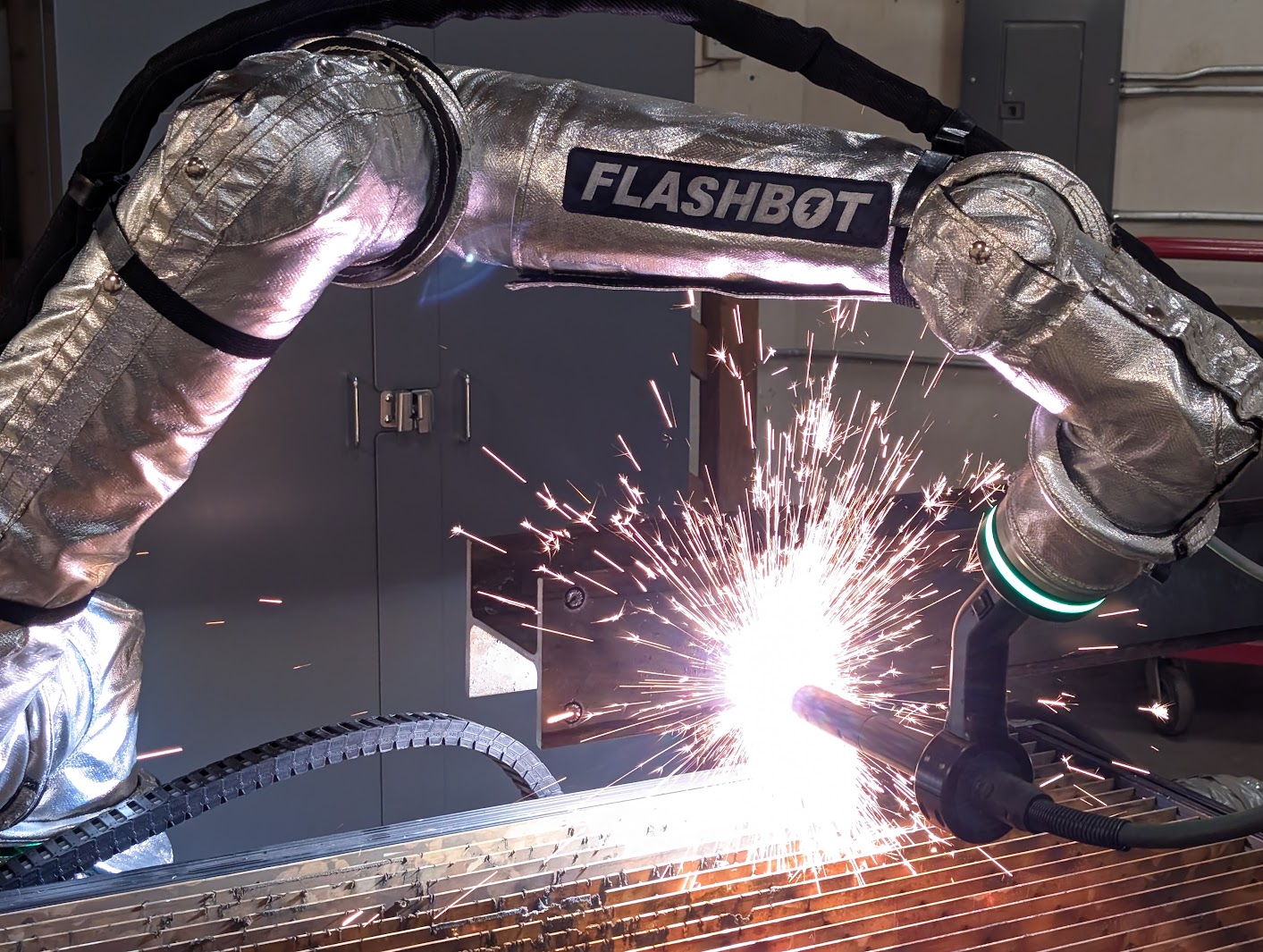

FlashBot® combines FlashCut’s® decades of expert plasma CNC with the latest in robotic technology.

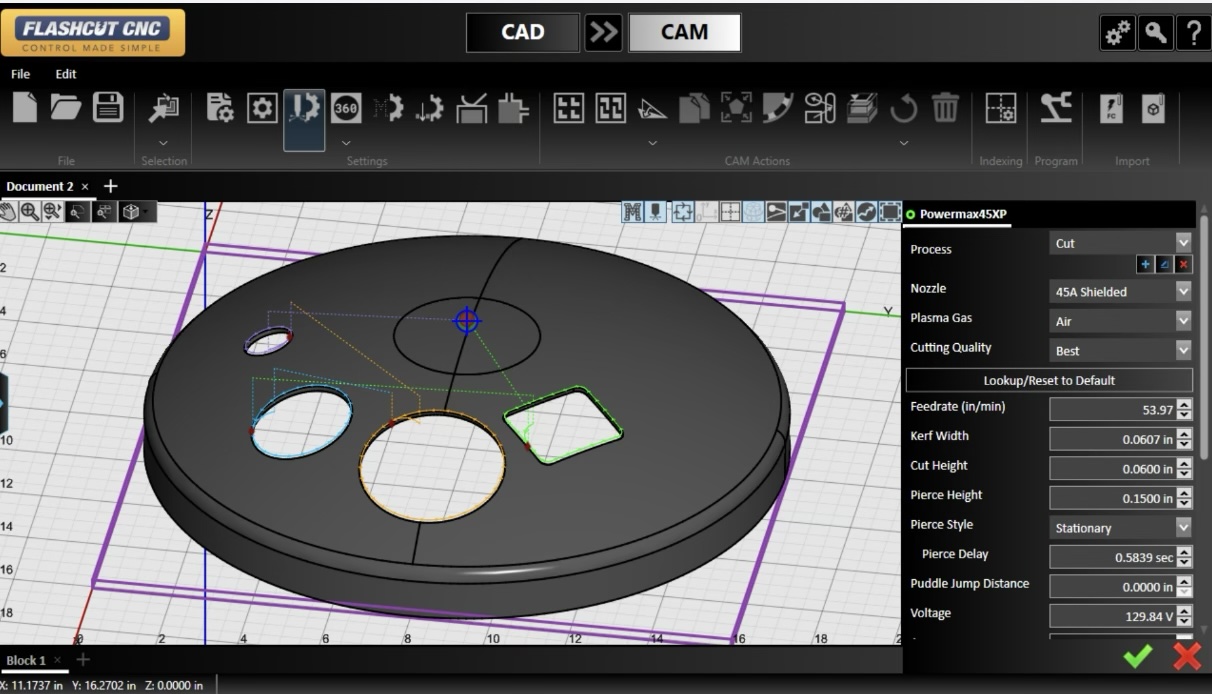

This cutting-edge product seamlessly takes your design from CAD to CAM to Cobot/Robot plasma cutting, making it a game-changer for your industrial cutting needs. Our platform offers the flexibility to import files or draw toolpaths using our world-renowned CAD/CAM software.

Great for Cutting:

- Structural Beams

- Domes

- Round Pipes

- Rectangular or Square Tubes

- Flat Sheets

- Beveled Holes

Ergonomic Plasma End-Effector with Laser Sensing and Torch Height Control

- Our integrated laser sensor can quickly scan your part surfaces and edges with an accuracy of 0.01mm

- Stingray® Torch Height Control maintains a precise cut-height for the ultimate part and feature accuracy

- LED Indicator lets you know what mode the robot is in at all times

- Our Unique Free-Drive Switch has two modes: maintaining free-drive on or off, or momentary free-drive

- FlashBot’s teach button is ergonomically placed to teach points or change modes with one button press

- The Customizable torch holder can fit any size plasma torch, from a small air plasma to a large Hi-Definition plasma

Easily Teach Custom Cut Paths & Shapes

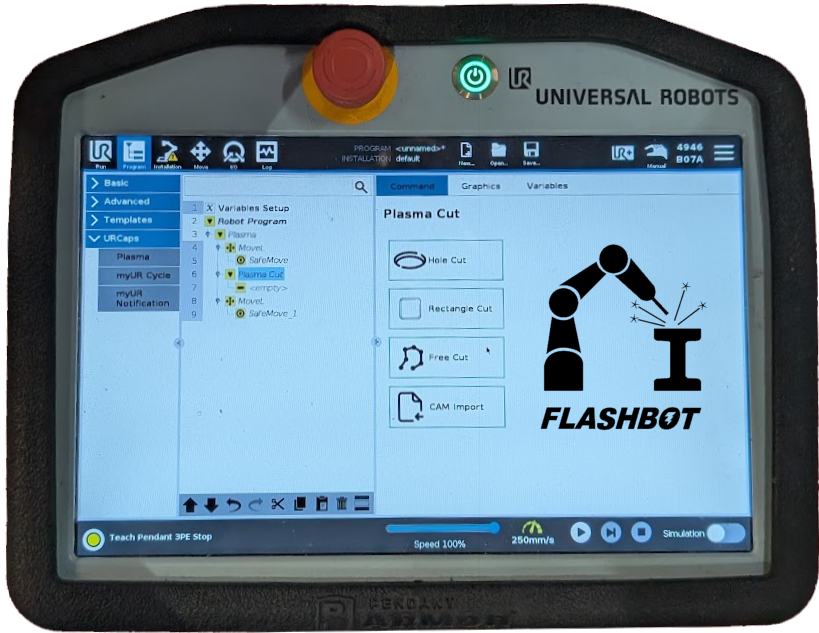

FlashBot simplifies the complex task of teaching custom toolpaths for plasma cutting. Whether you’re an experienced technician or a novice, our intuitive interface makes it a breeze to create precise toolpaths along with accurate holes and slots with just a few clicks.

Expert Integration with World-Class Cobots/Robots and Plasma Machines

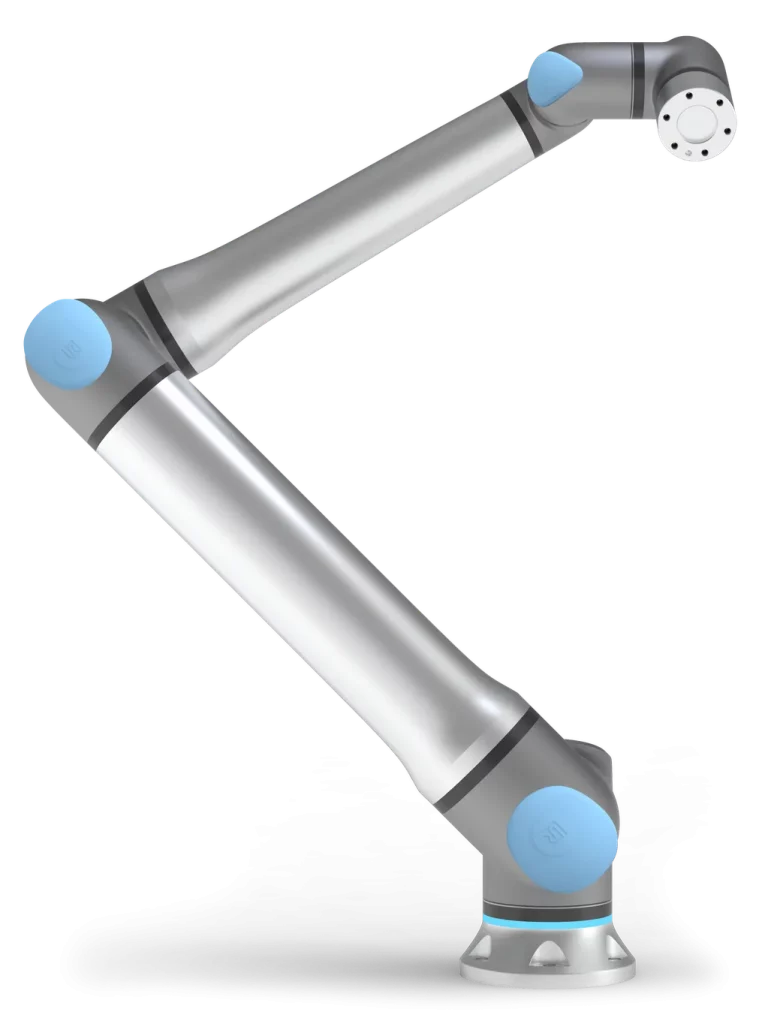

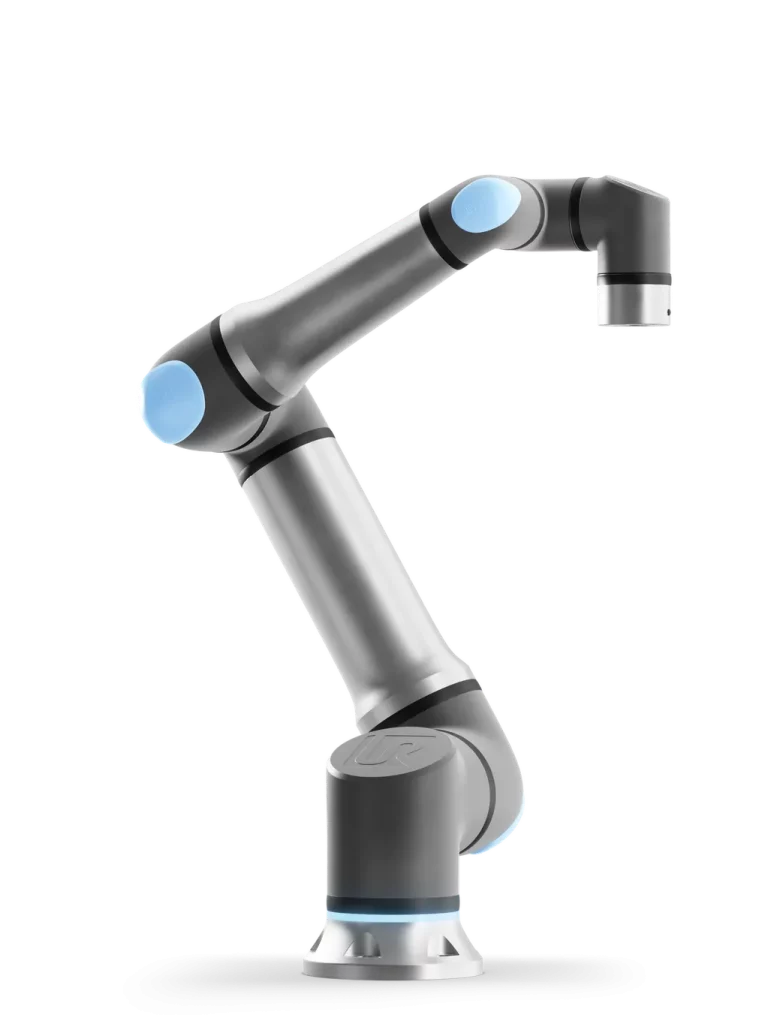

We understand the importance of working with top-tier collaborative robots like the Universal Robots® UR 5, 10, 20 and 30. That’s why we’ve tailored our interface to integrate with these industry-leading cobots seamlessly. This ensures that your production process is efficient and in sync with the latest advancements in robotics.

We have decades of experience in controlling world-leading plasma machines like Hypertherm® Powermax®, MaxPro200®, HPR®, XPR® and the Kjellberg® Smar

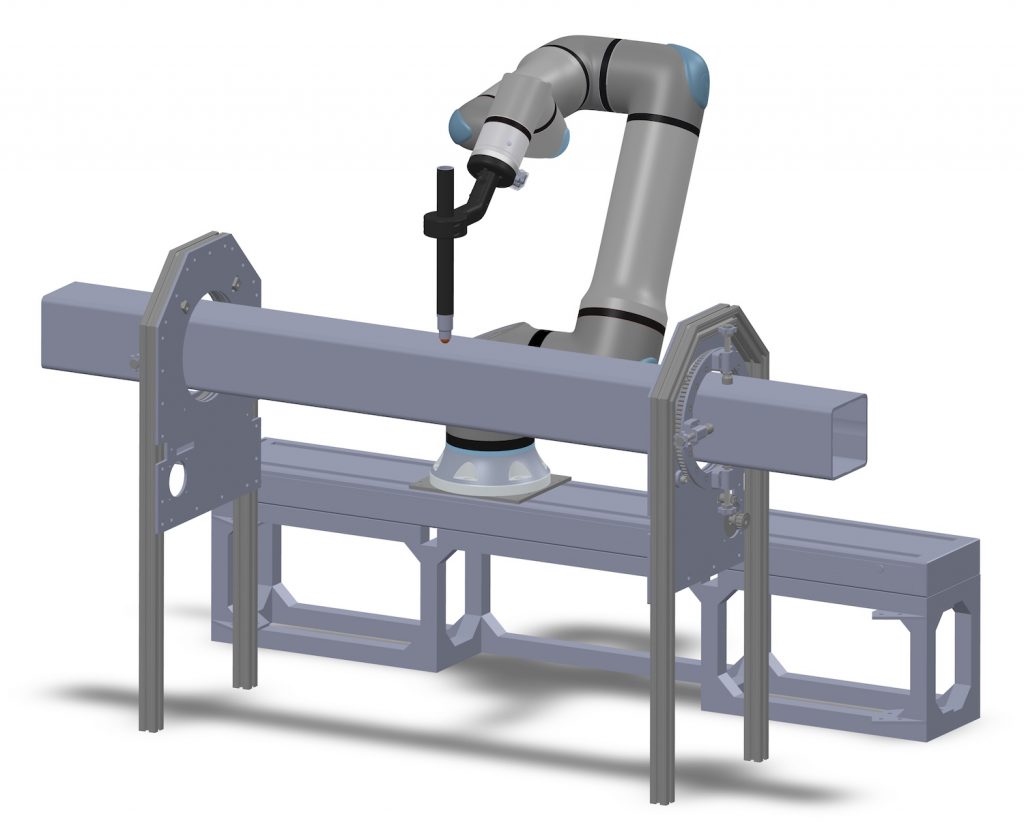

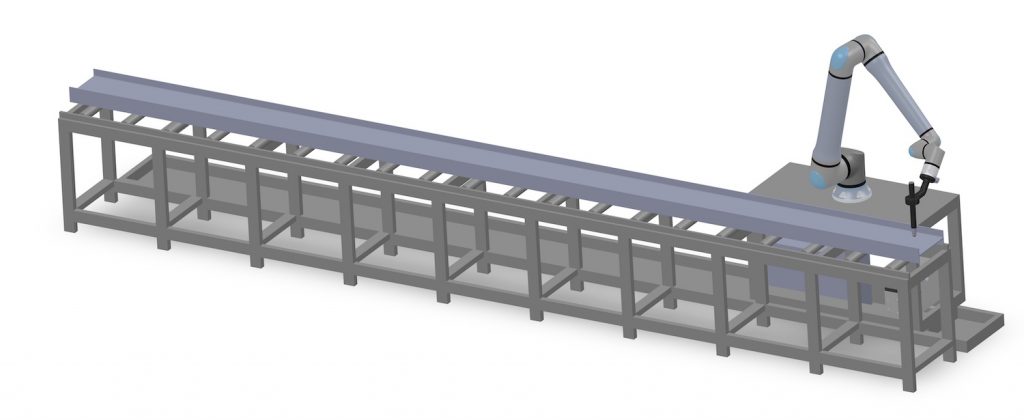

Integration with External Axes

We understand that every application is unique. That’s why we’ve designed our system to seamlessly integrate cobot motion with multiple external axes using EtherCAT® communications. Whether you need a linear slide or a rotary chuck, our platform can adapt to your specific needs, ensuring maximum flexibility in your production setup.